Precision CNC Machining Services

Over 45 Years of Excellence

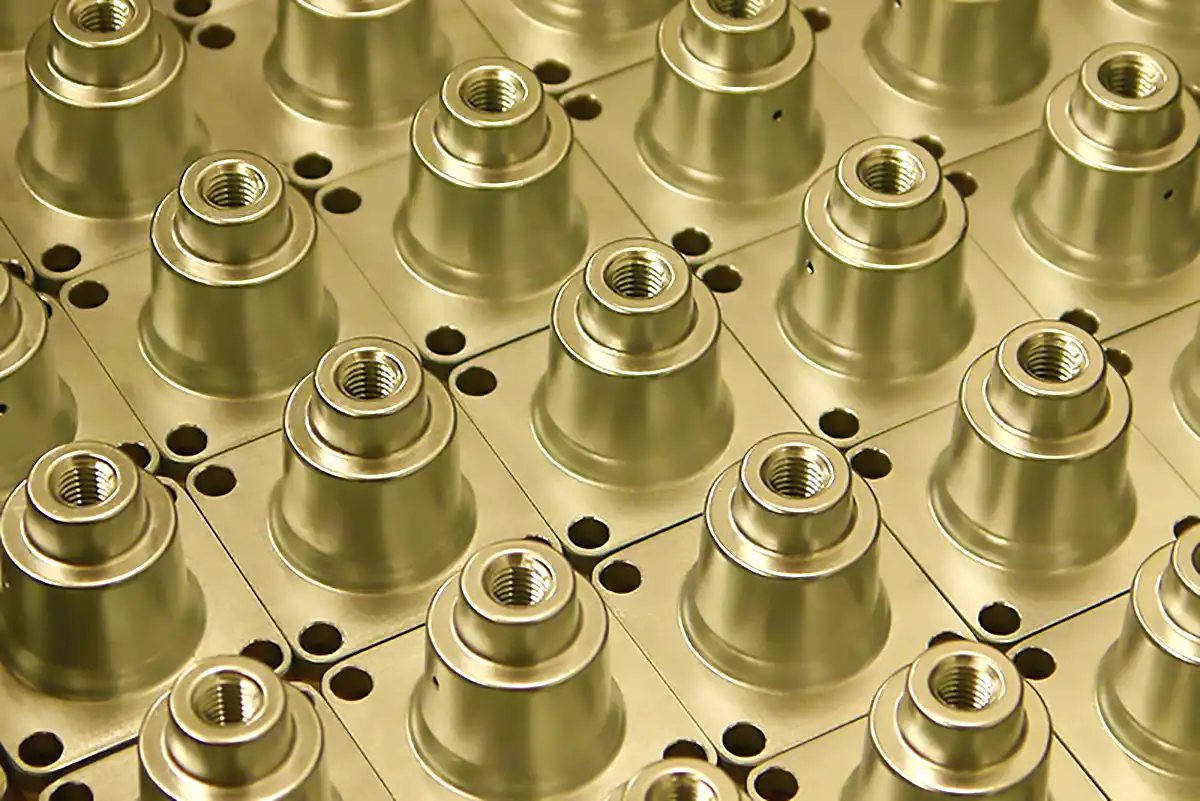

Graphicast has provided precision-machined zinc alloy castings for over 45 years. During that time, we have continued to purchase state-of-the-art equipment to ensure we are meeting our customers’ increasing quality and performance standards. We are now offering these same machining services to the broader market looking for machined parts of various materials – not just precision castings by Graphicast.

Our extensive experience in precision CNC machining, combined with our commitment to technical excellence and ISO 9001:2015 certification, positions us as your ideal partner for low to medium-volume production runs. Whether you require complex geometrical parts, tight-tolerance components, or specialized machining solutions, our team delivers the precision and quality your projects demand. Contact us today to learn more about Graphicast’s new CNC machining services and how we can support your manufacturing needs.

Connect with Our Engineering Team

Have questions about how our custom metal casting services can optimize your components? Our technical experts are ready to review your requirements and provide specific recommendations for your application.

State-of-the-Art Equipment List

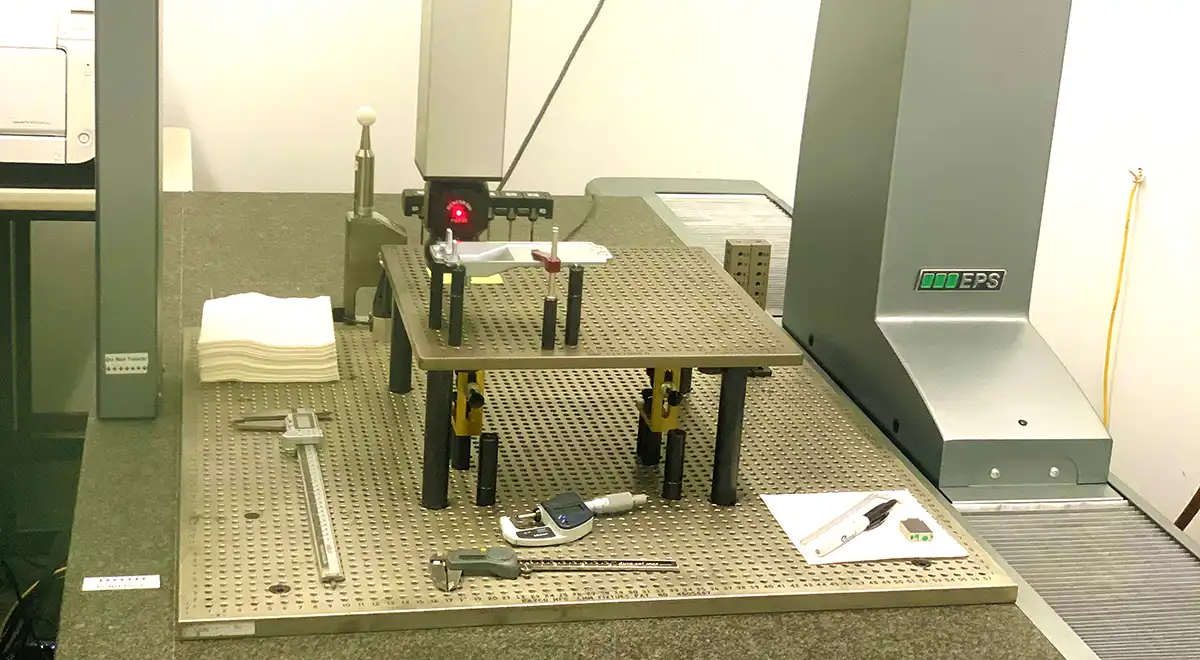

Our facility in Jaffrey, New Hampshire, features an impressive array of precision CNC machining equipment, designed to handle a wide range of manufacturing challenges. We’ve strategically invested in technology that provides both versatility and precision, ensuring we can meet your specific requirements regardless of complexity or material specifications.

CNC Machining Centers (all VMC fitted with Haas Rotary Tables)

- Haas VF-2SSYT – Sept 2020 (internal probe)

- Haas VF-3SSYT – Dec 2021 (internal probe)

- Haas VF-3SSYT – Dec 2021 (internal probe)

- Mazak 410B – 2003

- Mazak 410B – May 2012

- Mazak 410B – May 2012

- Haas TM-1P – September 2024 (specialized graphite machining)

Tool Pre-setter

- Zoller 420 – 2018

CMMs

- Mitutoyo CRTPM574 CMM – 2018

- Hexagon Global S 07.10.07 Automated CMM – 2020

Additional Equipment

- TESA Electronic Height Gauges

- De-burring & Tumbling Equipment with both plastic and ceramic media

This comprehensive equipment configuration ensures that your projects won’t face delays due to machine availability, allowing us to select the optimal equipment for your specific requirements. Our specialized Haas TM-1P for graphite machining showcases our commitment to maintaining equipment optimized for specific materials and applications. At the same time, our Zoller 420 tool pre-setter ensures precise tool measurements before machining begins, contributing to exceptional accuracy and reducing setup times.

Our quality assurance capabilities include:

Quality Assurance Through Advanced Measurement Technology

Quality control forms the foundation of our precision CNC machining services. Our investment in advanced measurement technology demonstrates our commitment to delivering parts that consistently meet or exceed your specifications.

Our quality assurance capabilities include:

- Mitutoyo CRTPM574 CMM for detailed dimensional verification

- Hexagon Global S 07.10.07 Automated CMM for high-volume inspection efficiency

- TESA Electronic Height Gauges for rapid dimensional checks

- Comprehensive first article inspection reports

- In-process quality monitoring protocols

This sophisticated measurement infrastructure enables us to maintain true position tolerances of 0.002 inches for standard holes and surface-to-surface tolerances of ±0.0005 inches for dimensions under 6 inches. For larger dimensions exceeding 6 inches, we maintain ±0.001-inch tolerances, ensuring your parts meet the most demanding specifications.

Graphicast’s Engineering Staff & Software Capabilities

Our entire engineering staff brings years of relevant experience to every project, offering consultation and collaboration throughout the manufacturing process. We understand that successful CNC machining services require more than just equipment; they demand expertise in design optimization, material selection, and process refinement.

Engineering Software:

- SolidWorks

- CREO

- FeatureCAM

- Predator

We work seamlessly with your existing CAD files using our comprehensive software suite, ensuring smooth data transfer and eliminating potential errors that can occur during file conversion. Our engineers can review your designs for manufacturability, suggest modifications to reduce costs without compromising quality, and optimize tool paths for efficient production.

The combination of engineering expertise and advanced software capabilities allows us to tackle complex projects that other machine shops might find challenging. Whether you’re transitioning from prototype to production or need assistance optimizing an existing design, our team provides the technical support necessary for project success.

Single Source Services and Finishing Options

Beyond precision CNC machining, we offer comprehensive value-added services that eliminate the need for multiple vendors, streamlining your supply chain. Our single-source approach ensures consistent quality across all operations, simplifying your vendor management requirements.

Single Source Services:

- Painting

- Chromating

In-House Capabilities:

- Dot peen part marking for permanent identification

- De-burring and tumbling with both plastic and ceramic media

- Light assembly services, including pins, PEMs, bushings, and bearings

Additional Finishing Options:

- Powder coating through trusted partners

- Protective finishes

- Cerakote and e-coat applications

These integrated services mean you receive fully finished parts ready for implementation, reducing your administrative burden and accelerating time to market.

ISO 9001:2015 Certified Quality Management

Our ISO 9001:2015 certification represents more than compliance; it demonstrates our systematic approach to quality management and continuous improvement. This certification covers both our casting and precision machining operations, ensuring consistent quality across all services.

The ISO framework guides our processes from initial quote through final delivery, encompassing material traceability, process documentation, and comprehensive quality records. Every part we produce is backed by our quality management system, providing you with confidence in our ability to consistently meet your requirements.

Ideal for Low to Medium Volume Production

Our CNC machining services excel in the economically challenging space of low- to medium-volume production, typically ranging from 100 to 20,000 parts annually. Unlike high-volume operations that require significant minimum orders, we’ve structured our operations specifically for smaller production runs without sacrificing quality or cost-effectiveness.

This specialization enables us to offer competitive pricing for prototype development, pilot production runs, and low-volume ongoing requirements. Our setup procedures, tooling strategies, and scheduling systems are optimized for quick changeovers, allowing us to transition efficiently between different projects while maintaining precision and quality.

For companies seeking an alternative to expensive in-house machining or high minimums with offshore suppliers, our services provide the perfect balance of quality, flexibility, and cost-effectiveness. We understand the unique challenges of low-volume manufacturing and have developed our processes specifically to address these needs.

Single Source Services

- Painting

- Chromating

Full Engineering Staff

- Consultation

- Collaboration

- Years of relevant experience

Engineering Software:

- SolidWorks

- CREO

- FeatureCAM

- Predator