Custom Metal Casting Services

Making the Choice between Good, Fast, and Cost Effective - Unnecessary

Custom Graphite Mold Casting: A Better Way Forward

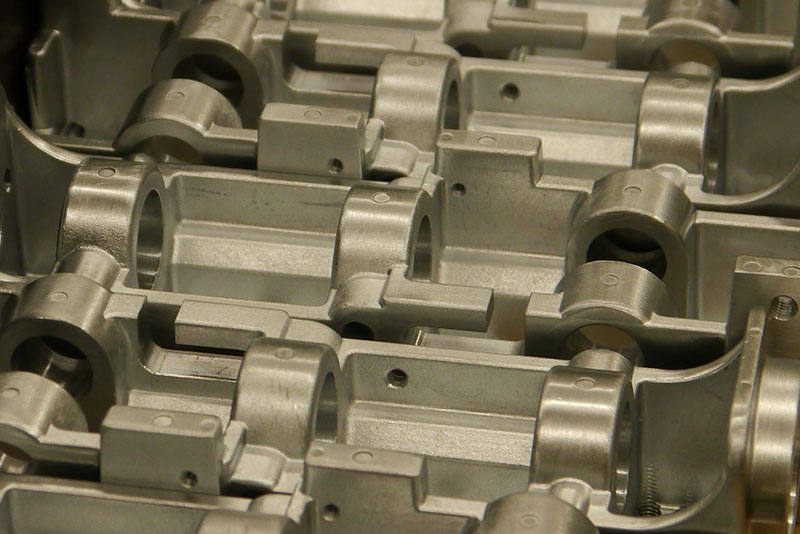

Graphicast understands that time is often critical for your success. Our proprietary LTA™ casting technology utilizes graphite mold casting to create net and near-net shape parts in the high-performance ZA-12 alloy. This approach delivers precision, consistency, and cost-efficiency, making it an ideal solution for manufacturers seeking high-quality custom metal castings.

For over 40 years, we have helped OEMs (Original Equipment Manufacturers) streamline their production processes with our unique combination of innovative design, premium materials, and advanced casting techniques. The result? Faster turnaround times, better quality parts, and significant savings compared to traditional casting methods.

Learn more about our process below, or contact us today to discuss how our metal casting services can elevate your project.

The Advantages of Graphite Mold Casting with ZA-12 Alloy

Graphicast’s permanent graphite molds paired with ZA-12 alloy offer a powerful combination for various industries and applications. Here’s why they stand out:

- Precision and Repeatability: Graphite molds allow for highly accurate castings with consistent dimensions.

- Faster Production Times: Our proprietary LTA™ casting process reduces lead times, enabling us to move from design to finished part in under six weeks.

- Cost Savings: The durability of graphite molds and the cost-effective properties of ZA-12 alloy lower your overall acquisition costs.

- Superior Material Properties: ZA-12 alloy provides exceptional strength, corrosion resistance, and machinability, making it a versatile choice for demanding applications.

Whether you’re transitioning from traditional methods like sand casting or investment casting, or exploring alternatives to plastic injection molding, our custom metal casting services deliver better results with fewer headaches.

Compare Graphite Mold Casting to Other Methods

Advantages Over Alternative Casting Methods:

- Graphite Mold Casting vs. Aluminum Casting: ZA-12 offers superior strength and wear resistance.

- Graphite Mold Casting vs. Brass or Bronze Casting: Achieve comparable durability at a fraction of the cost.

- Graphite Mold Casting vs. Injection Molding: Lower tooling costs and better performance for small to medium production runs.

Graphicast’s expertise ensures that our custom metal castings meet your unique specifications while outperforming other casting techniques.

Get Started Today

Ready to see how graphite mold casting can enhance your production? Graphicast’s team of experts is here to help you design, produce, and deliver parts that exceed expectations. Contact us today to discuss your project and experience the benefits of our metal casting services firsthand.