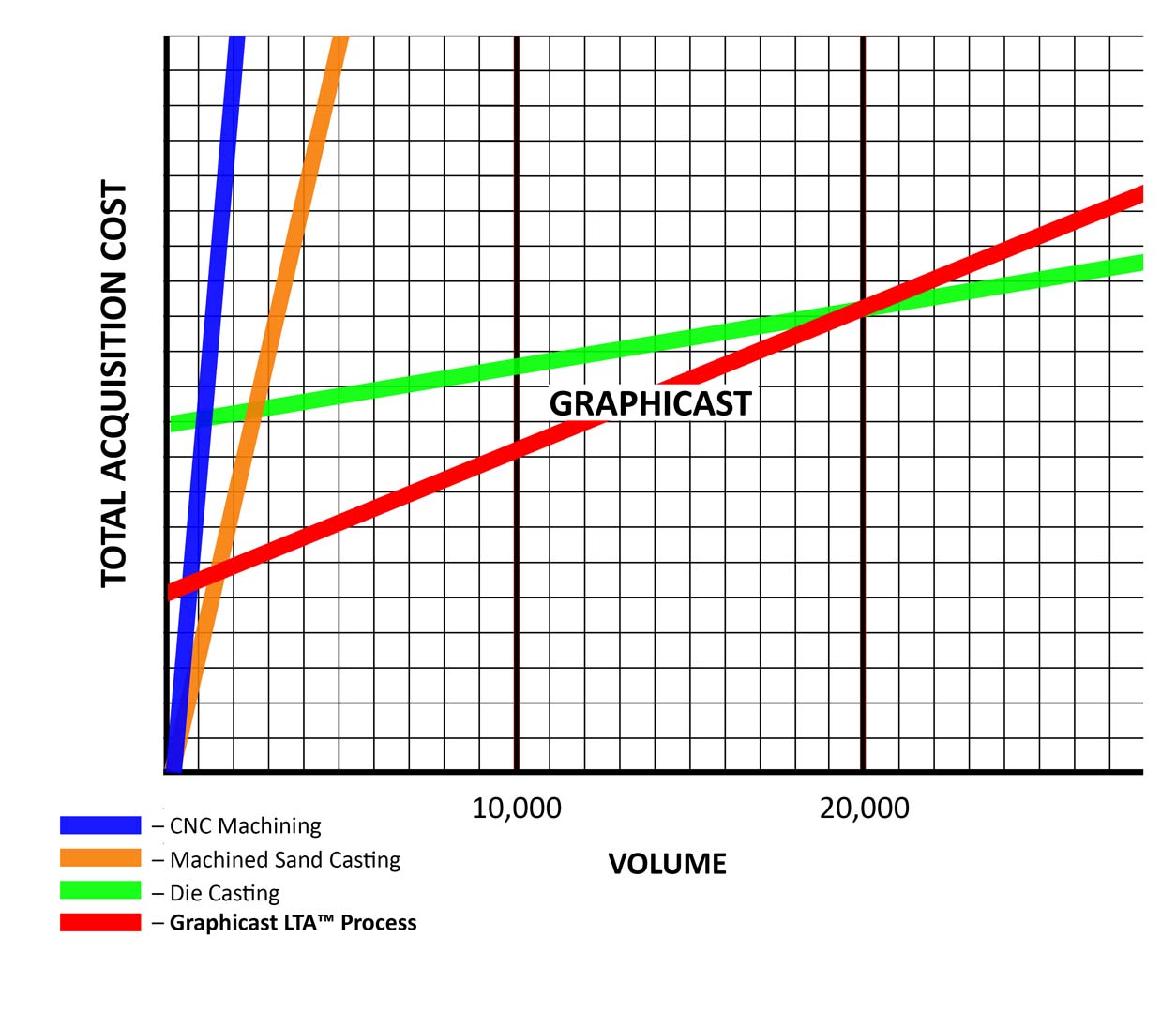

Lower Total Acquisition Cost

The economic advantages of the Graphicast process lie in lower total acquisition costs as a result of reduced tooling costs, the reduction or elimination of secondary machining operations, and shorter time to market.

Contact Us today, and we’ll show you how your total acquisition costs can be lower for production runs of 100 to 20,000 parts per year.

Compared to Machined Sand Castings

Parts produced through the Graphicast process have dramatically lower total cost per part and significantly better finishes and appearance than machined sand castings.

Compared to Die Castings

Compared to die casting, the Graphicast process has much lower tooling costs which can be amortized over shorter production runs. Graphicast castings also have a more homogeneous structure than die cast parts.

Compared to Investment Castings

The Graphicast process produces parts with accuracies and surface finishes as good or better than investment cast parts, but with a much lower cost per part.

Low Cost. High Quality

Graphicast’s proprietary LTA™ process yields lower total acquisition cost for production volumes of 100 to 20,000 parts per year. More info on our low and medium volume manufacturing process available here.

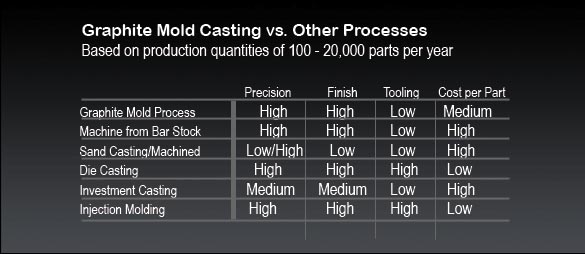

Graphite Mold Casting vs. Other Processes

(Based on production quantities of 100 to 20,000 parts per year)