Custom Metal Casting Services

Precision Without the Premium Price Tag

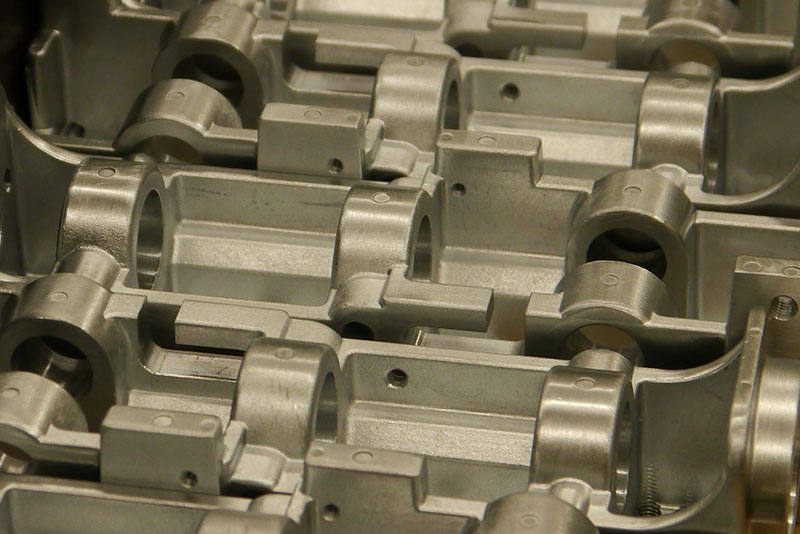

When manufacturers need custom metal casting services that deliver exceptional quality without excessive tooling costs or lengthy lead times, the choice becomes clear. At Graphicast, we’ve revolutionized the metal casting process through our proprietary LTA™ (Low Turbulence Auto-fill) technology, combining permanent graphite molds with high-performance ZA-12 zinc-aluminum alloy to create precision components that outperform traditional casting methods.

For over 47 years, we’ve helped OEMs streamline their production processes by eliminating the traditional trade-offs between quality, speed, and cost. Our unique graphite mold casting process excels in low- to medium-volume production runs, ranging from 100 to 20,000 parts annually, filling the critical gap between expensive die casting and less precise sand casting methods.

Connect with Our Engineering Team

Have questions about how our custom metal casting services can optimize your components? Our technical experts are ready to review your requirements and provide specific recommendations for your application.

The Science Behind Superior Custom Metal Casting

Our custom metal casting services utilize the exceptional properties of graphite molds, paired with ZA-12 alloy, to achieve results that traditional casting methods struggle to match. The graphite mold casting process creates net and near-net shape parts with surface finishes superior to sand casting and dimensional accuracies rivaling investment casting, all while maintaining significantly lower tooling costs than die casting operations.

The ZA-12 alloy we specialize in offers mechanical properties that often exceed those of aluminum, brass, and bronze castings. With tensile strength reaching 50,000 psi and excellent corrosion resistance, this zinc-aluminum alloy provides the durability and performance characteristics essential for demanding applications in medical equipment, industrial automation, and precision instrumentation.

Key Advantages of Our Graphite Mold Process:

- Economical tooling costs – Permanent graphite molds cost approximately $2,500, a fraction of die casting tooling

- Rapid production timeline – Move from CAD design to first production parts in just 4-6 weeks

- Superior surface finish – Achieve 125 RMS or better, reducing or eliminating secondary machining

- Complex geometries – Create intricate designs with thin walls (minimum 0.125″) and precise tolerances

- Design flexibility – Graphite molds can be easily modified mid-production to accommodate design changes

- Consistent quality – ISO 9001:2015 certified processes ensure repeatable, high-quality results

Engineering Excellence in Every Cast

What separates Graphicast’s custom metal casting services from conventional alternatives is our comprehensive engineering support throughout the entire production cycle. Our team collaborates with customers from initial concept through final production, optimizing designs to maximize the benefits of our casting process while minimizing secondary operations and overall costs.

The permanent mold casting process we employ produces parts with exceptional dimensional stability and repeatability. Unlike sand casting, which requires new patterns for each production run, our graphite molds maintain their precision through thousands of casting cycles. This consistency translates directly into reduced inspection requirements, lower scrap rates, and more predictable production schedules for our customers.

Our facility in Jaffrey, New Hampshire, houses state-of-the-art equipment specifically configured for graphite mold casting production. This includes advanced CNC machining centers for mold creation and finishing operations, as well as Mitutoyo and Hexagon CMMs for quality verification, and comprehensive secondary processing capabilities. By maintaining these capabilities in-house, we control every aspect of the production process, ensuring faster turnaround times and consistent quality standards.

Material Properties That Make the Difference:

- Density: 0.218 lb/cu in – lighter than brass or bronze

- Hardness: 110-125 Brinell – excellent wear resistance

- Melting range: 710-810°F – lower energy requirements than aluminum

- Machinability: Superior to most cast alloys, reducing finishing costs

- Corrosion resistance: Excellent performance in challenging environments

Applications Where Precision Matters

Our custom metal casting services have proven particularly valuable for manufacturers in industries where precision, reliability, and cost-effectiveness converge. Medical device manufacturers rely on our process for producing complex components that meet stringent regulatory requirements while maintaining economical production costs. Industrial automation companies rely on our casting services to create durable, precision parts that withstand continuous operation in demanding environments.

Laboratory and analytical equipment manufacturers have discovered that our graphite mold casting process delivers the tight tolerances, and excellent surface finishes their applications demand, often eliminating the need for extensive post-casting machining. The natural lubricity and wear resistance of ZA-12 alloy make it an ideal choice for moving parts, bearings, and components subjected to repeated mechanical stress.

Comprehensive Solutions Beyond Casting

While our graphite mold casting forms the foundation of our services, Graphicast offers complete turnkey solutions that extend well beyond the initial casting process. Our CNC machining services provide precision finishing when required, utilizing the same quality standards and attention to detail that define our casting operations. For components requiring special finishes or coatings, our secondary operations include chromating, painting, powder coating, and assembly services.

This integrated approach means customers work with a single supplier from initial design through finished components, simplifying supply chain management and ensuring consistent quality throughout the production process. Our engineering team’s expertise in both casting and machining allows us to optimize the entire manufacturing process, identifying opportunities to incorporate features directly into the casting that traditionally require secondary machining.

Partner with Proven Expertise

Choosing the right custom metal casting service provider requires evaluating not just current capabilities but also long-term partnership potential. Graphicast’s 47-year history demonstrates our commitment to continuous improvement and customer success. As an employee-owned company (ESOP), every team member has a vested interest in delivering exceptional quality and service on every project.

Our low-to-medium volume manufacturing expertise makes us the ideal partner for companies seeking to avoid the high tooling costs and minimum quantities associated with die casting while achieving better quality than sand or investment casting can provide. Whether you’re transitioning from machined components to reduce costs, seeking alternatives to offshore production, or developing new products that require precise, cost-effective metal components, our custom metal casting services deliver measurable advantages.

The Graphicast Advantage extends beyond our unique casting process to encompass our entire approach to customer partnerships. We understand that successful manufacturing relationships require more than just technical capabilities – they demand responsive communication, flexible production scheduling, and a genuine commitment to solving customer challenges. Visit our resources section to access technical specifications, design guidelines, and case studies that demonstrate how our custom metal casting services have helped companies across diverse industries achieve their manufacturing goals.